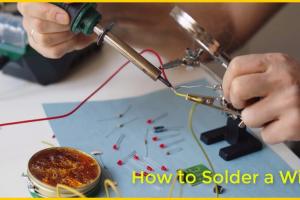

Mastering the Art of Soldering: A Comprehensive Guide to Soldering Wires Together

-

Quick Links:

- 1. Introduction

- 2. What is Soldering?

- 3. Why Soldering is Important

- 4. Tools and Materials Needed for Soldering

- 5. Soldering Techniques

- 6. Step-by-Step Guide to Soldering Wires Together

- 7. Common Mistakes to Avoid

- 8. Soldering Safety Precautions

- 9. Case Studies and Real-World Applications

- 10. FAQs

1. Introduction

Soldering is a fundamental skill for anyone interested in electronics, from hobbyists to professionals. Understanding how to solder wires together effectively can empower you to repair electronics, create new projects, and enhance your technical skills. This guide will take you through the entire process of soldering wires, covering everything from the basics to advanced techniques.

2. What is Soldering?

Soldering is a process of joining two or more electronic components together by melting solder, a fusible alloy, to form a permanent bond. This technique is crucial in the field of electronics for creating circuits and making connections between various components.

3. Why Soldering is Important

Soldering is important for several reasons:

- Durability: A well-soldered joint is strong and can withstand mechanical stress.

- Electrical Conductivity: Solder provides a low-resistance path for electrical current.

- Repairability: Soldering allows for easy repairs and modifications to electronic devices.

- Versatility: Useful in various applications, from DIY projects to industrial manufacturing.

4. Tools and Materials Needed for Soldering

To get started with soldering, you will need a few essential tools and materials:

- Soldering Iron: The primary tool for heating solder.

- Solder: A metal alloy used to join components; typically a mix of tin and lead or lead-free alternatives.

- Soldering Iron Stand: A safe place to rest your soldering iron when not in use.

- Soldering Flux: A chemical cleaning agent that helps the solder flow better and prevents oxidation.

- Wire Cutters: For trimming wires after soldering.

- Wire Strippers: To remove insulation from wires before soldering.

- Safety Goggles: To protect your eyes from solder splashes.

5. Soldering Techniques

Understanding different soldering techniques will enhance your ability to make strong connections. Here are some common techniques:

- Through-Hole Soldering: Involves inserting component leads through holes in a circuit board and soldering them on the other side.

- Surface Mount Soldering: Used for components that are mounted directly onto the surface of a PCB.

- Desoldering: The process of removing solder from a joint, often necessary for repairs.

6. Step-by-Step Guide to Soldering Wires Together

Follow these detailed steps to solder wires together effectively:

Step 1: Prepare Your Workspace

Ensure your workspace is clean, well-lit, and free of clutter. Gather all your tools and materials within reach.

Step 2: Strip the Wires

Use wire strippers to remove about 1/2 inch of insulation from the ends of the wires you want to solder together.

Step 3: Twist the Wires Together

For a secure connection, twist the exposed ends of the wires together. This step helps create a stronger bond when soldering.

Step 4: Heat the Soldering Iron

Plug in your soldering iron and allow it to heat up for a few minutes. A properly heated iron is essential for effective soldering.

Step 5: Apply Flux

Brush a small amount of soldering flux onto the twisted wires. This will help the solder flow better and create a strong bond.

Step 6: Solder the Wires

Touch the tip of the soldering iron to the twisted wires for a second to heat them. Then, feed solder into the joint until it flows and covers the exposed wire completely.

Step 7: Allow to Cool

Remove the soldering iron and allow the solder joint to cool naturally without disturbance. This will ensure a solid connection.

Step 8: Trim Excess Wire

Use wire cutters to trim any excess wire sticking out of the solder joint, ensuring a neat finish.

7. Common Mistakes to Avoid

Here are some common mistakes to avoid when soldering:

- Insufficient Heating: Not heating the wire enough leads to weak joints.

- Using Too Much Solder: Excess solder can create shorts or messy joints.

- Neglecting Safety: Always wear safety goggles and work in a well-ventilated area.

8. Soldering Safety Precautions

Safety is paramount when soldering. Here are some important safety precautions:

- Always wear safety goggles to protect your eyes from solder splashes.

- Work in a well-ventilated area to avoid inhaling fumes from heated solder and flux.

- Keep your workspace tidy and free from flammable materials.

- Be cautious with hot tools—always place the soldering iron in its stand when not in use.

9. Case Studies and Real-World Applications

Understanding real-world applications of soldering can enhance your knowledge and skills. Here are a couple of examples:

Case Study 1: DIY Electronics Project

A hobbyist built a custom Arduino project, making multiple wire connections that required soldering. By following proper techniques, they achieved a reliable circuit that functioned flawlessly.

Case Study 2: Repairing a Circuit Board

A technician repaired a faulty circuit board by desoldering broken connections and re-soldering new components. This process saved the device from being discarded and extended its life significantly.

10. FAQs

1. What type of solder should I use?

For most electronics, a rosin-core solder (either leaded or lead-free) is preferred due to its ease of use and excellent conductivity.

2. Can I solder without flux?

While it's possible, using flux greatly improves the quality of the solder joint by preventing oxidation and allowing solder to flow better.

3. How do I know if my solder joint is good?

A good solder joint should be shiny, smooth, and have a uniform shape, indicating proper heating and solder flow.

4. Is soldering safe?

When proper safety precautions are taken, soldering is generally safe. Always work in a ventilated area and wear protective gear.

5. How can I clean up soldering residue?

Use isopropyl alcohol and a small brush to clean up any soldering residue left on the circuit board after soldering.

6. What is the difference between through-hole and surface mount soldering?

Through-hole soldering involves inserting component leads through holes in a PCB, while surface mount soldering is done on the surface of a PCB without holes.

7. Can I solder wires without a soldering iron?

It is possible to use alternatives like soldering guns or even a hot air rework station, but a soldering iron is the most common tool for the job.

8. How do I remove solder from a joint?

Use a desoldering pump or wick to absorb the melted solder, or heat the joint and carefully pull the component away.

9. What is lead-free solder?

Lead-free solder is made without lead, often using a combination of tin, copper, and other metals. It is safer for health and the environment.

10. How long does it take for solder to cool?

Solder typically cools within a few seconds to a minute, depending on the size and mass of the joint.

Random Reads

- How to rekey locks without calling a locksmith

- How to open advanced settings in youtube

- How to treat carpet burns

- How to turn a voice memo into an mp3

- How to make a mansion on minecraft

- How to make a line graph

- How to remove fireplace insert

- How to replace broken glass in a picture frame

- How to splice coax cable

- How to use a microphone on pc