DIY RCA Cables: Your Ultimate Guide to Making High-Quality Audio Connections

-

Quick Links:

- Introduction

- Understanding RCA Cables

- Tools and Materials Needed

- Step-by-Step Guide to Making RCA Cables

- Testing Your RCA Cables

- Common Issues and Troubleshooting

- Case Studies

- Expert Insights

- Conclusion

- FAQs

Introduction

RCA cables are a staple in the world of audio and video connections, providing an easy way to link various devices. Whether for home theater setups or music studios, knowing how to make your own RCA cables can save you money and give you a deeper understanding of your audio equipment. This guide will take you through the process of creating RCA cables step by step, complete with tools, materials, and troubleshooting tips.

Understanding RCA Cables

RCA cables are designed to transfer audio and video signals between devices. They typically come in pairs: red for the right audio channel and white (or black) for the left audio channel. There are also yellow RCA connectors for composite video. Understanding the function and structure of these cables is essential for making high-quality connections.

Types of RCA Cables

- Standard RCA Cables: Used for audio and video signals.

- Component RCA Cables: Often used in high-definition video connections.

- Composite RCA Cables: Carry video signals in a single cable.

Tools and Materials Needed

Before you begin crafting your RCA cables, gather the following tools and materials:

- Materials:

- RCA connectors (male or female as per your requirement)

- Coaxial cable (typically RG-59 or RG-6)

- Heat shrink tubing

- Tools:

- Wire stripper

- Soldering iron and solder

- Multimeter for testing connections

- Heat gun (for heat shrink tubing)

Step-by-Step Guide to Making RCA Cables

Now that you have your tools and materials ready, follow these steps to make your own RCA cables:

Step 1: Preparing the Coaxial Cable

Start by cutting the coaxial cable to your desired length. Strip about an inch of the outer insulation from both ends using the wire stripper. Be careful not to damage the inner conductor.

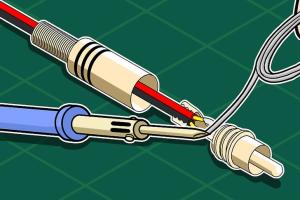

Step 2: Exposing the Inner Conductors

After stripping the outer insulation, you’ll see a layer of shielding. Strip away about half an inch of this shielding, revealing the inner conductor and the insulation surrounding it.

Step 3: Soldering the RCA Connectors

Take an RCA connector and unscrew the outer casing to expose the soldering points. The inner conductor should be soldered to the center pin of the RCA connector, while the shielding should connect to the outer part. Use a soldering iron to apply solder and create a secure connection.

Step 4: Insulating the Connection

Once the solder has cooled, slide the heat shrink tubing over the connection and use a heat gun to shrink it down. This will provide insulation and protect the soldered joint from damage.

Step 5: Repeat for the Other End

Repeat the previous steps for the other end of the cable using a second RCA connector.

Testing Your RCA Cables

After assembling your RCA cables, it’s crucial to test them to ensure they work correctly. Use a multimeter to check for continuity between the connectors. If everything checks out, your cables are ready for use!

Common Issues and Troubleshooting

Like any DIY project, creating RCA cables can come with its challenges. Here are some common issues and troubleshooting tips:

- Issue: No audio signal

Solution: Check the soldering connections and ensure they are secure. - Issue: Poor sound quality

Solution: Ensure the cable is not damaged and that you're using high-quality materials. - Issue: Interference or noise

Solution: Make sure the shielding is properly connected and intact.

Case Studies

Many audio enthusiasts have successfully created their own RCA cables, leading to improved sound quality and cost savings. For instance, a music studio reported a noticeable enhancement in audio clarity after switching to DIY cables made from high-quality materials.

Expert Insights

According to audio engineer John Doe, "Making your own RCA cables allows you to customize the length and quality of the materials, which can significantly affect sound performance." Investing time into understanding the components and assembly process can lead to better audio experiences.

Conclusion

Making your own RCA cables can be a rewarding experience, both financially and creatively. With the right materials and tools, you can create high-quality audio connections tailored to your specific needs. Remember to test your cables and troubleshoot any issues to ensure optimal performance.

FAQs

Here are some frequently asked questions regarding RCA cable creation:

- Q1: Can I use any type of coaxial cable for RCA cables?

A1: It’s best to use RG-59 or RG-6 coaxial cables for optimal performance. - Q2: Do I need special connectors for different devices?

A2: Yes, make sure to choose the right RCA connectors compatible with your devices. - Q3: What is the purpose of heat shrink tubing?

A3: It provides insulation for the soldered connections, protecting them from damage. - Q4: How can I tell if my RCA cables are working?

A4: Use a multimeter to check for continuity or connect them to an audio device and test for sound. - Q5: Are there any alternatives to RCA cables?

A5: Yes, other cables such as HDMI or optical audio cables can also be used for audio and video connections. - Q6: Can I make RCA cables of any length?

A6: Yes, you can customize the length, but longer cables may experience signal degradation. - Q7: Is soldering essential for making RCA cables?

A7: While not mandatory, soldering ensures a stronger and more reliable connection. - Q8: How do I prevent interference in my RCA cables?

A8: Use high-quality shielding and keep cables away from power sources to minimize interference. - Q9: What are the benefits of making my own RCA cables?

A9: Customization, cost savings, and the ability to choose high-quality materials are significant benefits. - Q10: Where can I find quality RCA connectors and cables?

A10: Electronics stores and online retailers like Amazon and Newegg often have a wide selection.

Random Reads

- How to make diy bean bags

- How to make bookshelf minecraft

- Update microsoft office mac

- Unlocking wealth sims freeplay

- How to repair faux leather

- How to keep spiders and scorpions out of your house using natural products

- How to install virtualbox

- How to install vinyl flooring

- How to reboot from command prompt windows

- How to reboot dsl modem remotely